ARC Ultimate

R 34,385.00 Incl. VAT

The ARC Ultimate is our flagship annealer, loaded with technology and features, taking brass annealing to the next level.

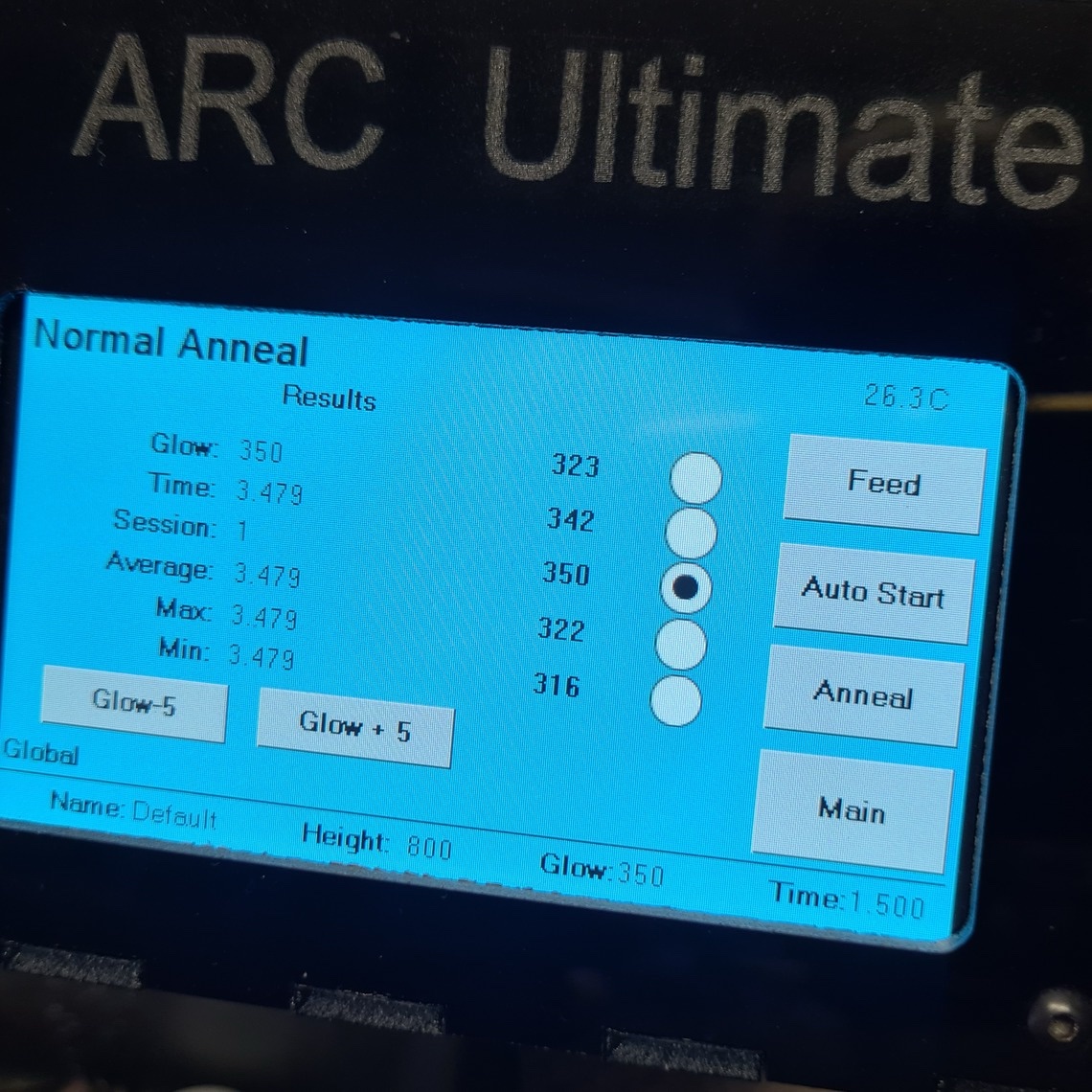

- ARC now utilize their Multi Head Thermal sensor (MHT). Giving the user total control and flexibility to monitor the annealing temperatures with 5 thermal sensors built-in, and standard with the Ultimate.

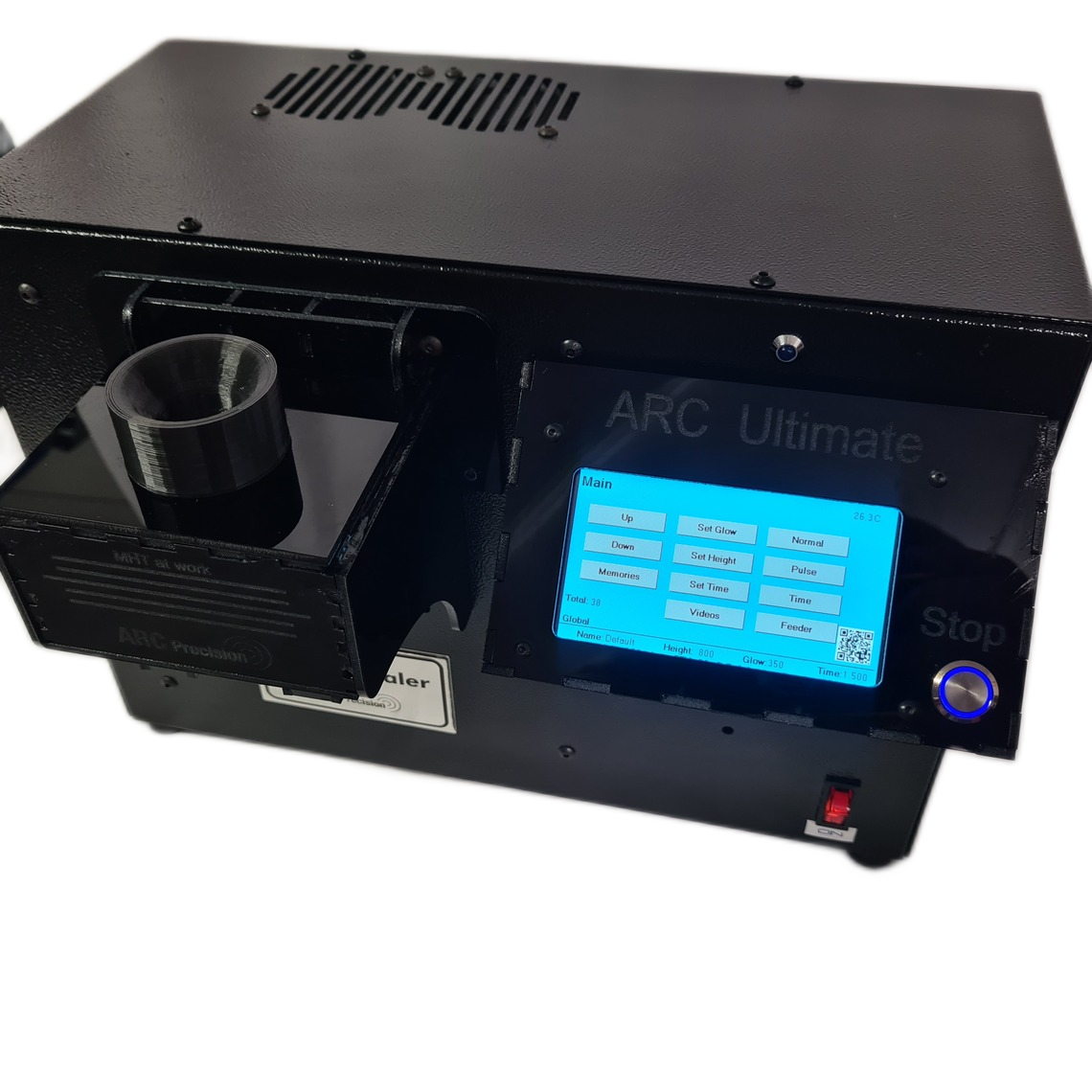

- The Ultimate comes standard with a no-nonsense feeder and Auto Start.

- The Feeder is constructed of laser cut Plexiglass and can hold 50 pieces of 7.62 brass(at least).

- A pre-heat cycle is included for Time, Pulse and Thermo-Anneal.

- The Touch Screen, graphical user interface and MHT makes annealing a pleasure, removing the uncertainty of mechanical neck pressure, delivering the ES you require.

- The Ultimate boasts with a 1000 memories and no limit between Time, Pulse or Thermal (Glow) memories.

- ARC is prepared for all languages and already provides for 4 languages.

- The motorized height control delivers accuracy with approximately 0.4mm between steps.

- Running cool at an average 350W allows the user to anneal large batches without delay while the internal fan control and manage any heat build up with alarm levels monitored.

- Our custom Ferrite core delivers deep and fast penetration, keeping heat where you want it.

- 8 Teflon fixtures are standard supplied, no need to purchase expensive additions fixtures for different calibers.

Reviews

There are no reviews yet.