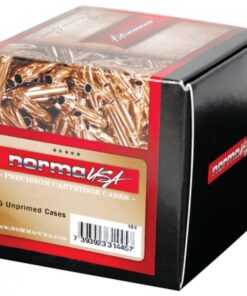

NORMA CASES .375 H&H (50)

Sorry, this product is not available to purchase in your country.

R 2,227.00 Incl. VAT

Norma Brass 375 Holland and Holland Mag.

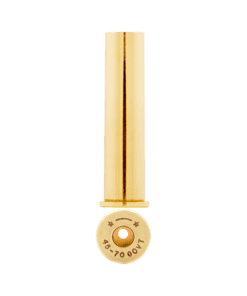

375 H&H Mag.

When Holland & Holland designed this cartridge in 1912 a bullet diameter of .375” was considered a light medium bore. However, due to the relatively moderate recoil and the modern bullet design it soon became the most popular all-round cartridge for African hunting and has been so ever since. Due to the narrow shoulder of the cartridge the designers decided to incorporate a belt just behind the rim. Accordingly the cartridge originally was give the impressive title of: “ Holland & Holland’s .375 Belted Rimless Magnum Express.

The .375 was designed for use in a magnum length action, but as these were scarce before WW II many English gunmakers removed metal in front of the lower locking-lug in order to sufficiently enlarge the magazine of standard-length Mauser actions. As both options were costly, the case was soon used as a basis for a number of wildcats and commercial “short magnum” cartridges.

By modern standards one could consider the .375 H&H a .30-06 using a 9,5mm bullet, which isn’t a bad designation at all. With pointed bullets the .375 has a sufficiently flat trajectory to be used on most species, although unnecessary powerful for anything but the largest deer and bears in North America. It is also quite popular for moose hunting in Scandinavia, but it’s in Africa with her wide variety of antelopes and other game species that one can use the full potential of this great cartridge. With proper bullets the .375 it can be and is often being used for hunting buffalo and elephant, but it cannot be considered the best choice for this purpose.

Norma products are known worldwide for high quality. Cartridge cases are an important factor in this reputation. Superior quality ensures a long life and many reloads. Norma cases are made of the best possible raw materials with the narrowest tolerances, and they deliver accuracy round after round.

The case neck is annealed to become softer. This prevents gas leaks and enables the case to hold the bullet firmly for at least 10 years without cracking as a result of aging material.

Further down on the case body, the hardness increases to avoid unnecessary stretching. If it is too hard, it would bring the risk of cracks.

Furthest down, around the primer pocket, the brass should be firm. Here, the hardness is nearly twice that of around the neck.

The structure of the material reveals the hardness. During processing the large, soft grains are broken down into smaller ones, which makes for a harder material. At the annealing, small grains become bigger and the hardness decreases.

| Weight | 1.5 kg |

|---|---|

| Dimensions | 25 × 15 × 15 cm |

Be the first to review “NORMA CASES .375 H&H (50)” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.