Norma Cases 222 Rem QTY 100

Sorry, this product is not available to purchase in your country.

R 2,317.00 Incl. VAT

Norma Cases 222 Rem QTY 100

The triple deuce was an instant success when Remington marketed it in their then new 722 bolt action rifle in 1950. Designed mainly by Mike Walker the case was an entirely new development and not based on any existing cartridge. In many respects it is a scaled-down version of a .30-06, and the base diameter of the case soon became a standard which many other cartridges would use.

Due to the high precision potential of the cartridge, its flat trajectory and the mild recoil it quickly became popular amongst benchrest shooters as well as hunters in both the US and Europe.

In spite of the many examples of large game successfully killed with the .222 it is not really suited to hunting whitetails and has accordingly been banned for this use in many states. For the USA it remains a small game cartridge – but one of the best of its kind – easy and cheap to reload with a wide variety of bullets to choose from. It is very effective out to approximately 200 yards which is the practical limit anyway for most people that only occasionally goes varmint hunting.

For the European hunter, however, .222 Remington is a very good choice for all small game up to and including the European roe deer, which rarely exceeds 70 pounds. With proper loads it is very versatile and non-destructive on the game whether the target is a fox on the ground or a Black Cock in the top of a birch tree at 200 meters.

Due to the standard twist of 1 in 14 inches the .222 Remington rarely performs well with bullets over 60 grains and many rifles will not handle anything heavier than 55 grain bullets.

Norma products are known worldwide for high quality. Cartridge cases are an important factor in this reputation. Superior quality ensures a long life and many reloads. Norma cases are made of the best possible raw materials with the narrowest tolerances, and they deliver accuracy round after round.

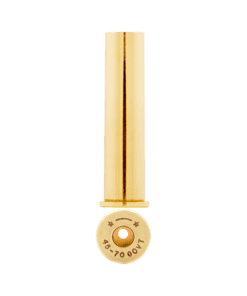

The case neck is annealed to become softer. This prevents gas leaks and enables the case to hold the bullet firmly for at least 10 years without cracking as a result of aging material.

Further down on the case body, the hardness increases to avoid unnecessary stretching. If it is too hard, it would bring the risk of cracks.

Furthest down, around the primer pocket, the brass should be firm. Here, the hardness is nearly twice that of around the neck.

The structure of the material reveals the hardness. During processing the large, soft grains are broken down into smaller ones, which makes for a harder material. At the annealing, small grains become bigger and the hardness decreases.

| Weight | 1.5 kg |

|---|---|

| Dimensions | 25 × 15 × 15 cm |

Be the first to review “Norma Cases 222 Rem QTY 100” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.