Norma Cases 243 Win QTY 100

Sorry, this product is not available to purchase in your country.

R 2,825.00 Incl. VAT

Norma Cases 243 Win QTY 100

The .243 Win. was originally a wildcat designed by Warren Page who necked down the .308 case in the early fifties. The goal was to make a light deer rifle which would still have the advantages of the high-velocity .22-calibers for varmint hunting. In 1955 Winchester made it a commercial round. The .243 is a very popular round all over the world for hunting medium sized game, probably due to its flat trajectory and very mild recoil. Surprisingly enough its popularity never reached the same degree when it comes to varmint hunting in spite of the .243” bullets better wind-bucking capabilities.

In Europe, however, the .243 suffers from the fact that only in Scotland does it meet the legal requirements for a big game cartridge to be used on anything larger than roe deer.

For small game and varmint hunting bullets in the 70-85 grain range are suitable, but normally the expansion of theses bullets are too rapid to give the necessary penetration needed for quick kill on larger game from pronghorn antelope and upwards. For this bullets weighing 90-100 grains are a much better choice. Although one shot kills have been made on much larger animals than Mule Deer, the .243 is not an elk rifle by any reasonable standard.

For hunting edible birds and fox the full metal jacketed bullets will do a much better job than the equivalent bullets in .22-caliber does.

Norma products are known worldwide for high quality. Cartridge cases are an important factor in this reputation. Superior quality ensures a long life and many reloads. Norma cases are made of the best possible raw materials with the narrowest tolerances, and they deliver accuracy round after round.

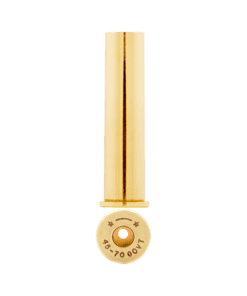

The case neck is annealed to become softer. This prevents gas leaks and enables the case to hold the bullet firmly for at least 10 years without cracking as a result of aging material.

Further down on the case body, the hardness increases to avoid unnecessary stretching. If it is too hard, it would bring the risk of cracks.

Furthest down, around the primer pocket, the brass should be firm. Here, the hardness is nearly twice that of around the neck.

The structure of the material reveals the hardness. During processing the large, soft grains are broken down into smaller ones, which makes for a harder material. At the annealing, small grains become bigger and the hardness decreases.

| Weight | 1.5 kg |

|---|---|

| Dimensions | 25 × 15 × 15 cm |

Be the first to review “Norma Cases 243 Win QTY 100” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.