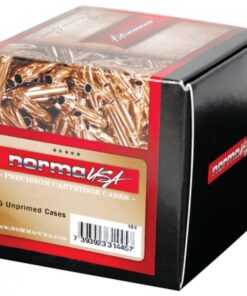

Norma Cases 338 Win Mag QTY 50

R 1,838.00 Incl. VAT

Norma Cases 338 Win Mag QTY 50

Two years after the introduction of the short .458 Win. Mag, two cartridges with unusual bullet diameters were marketed by Winchester. Quite unusually they were both named using their true bullet diameters. After a good start the .264 Winchester Magnum turned out not entirely to be what it was supposed to and it quickly began to fade away. But its big brother hit it big. The .338 Winchester Magnum is one of the most popular magnum cartridges for large American game. Not surprisingly, as it uses heavy bullets with a moderate velocity resulting in a well-controlled expansion and a very good penetration – the time proven recipe of an efficient killer. Maybe even more important the moderate velocity makes the recoil tolerable to most hunters. The trajectory is slightly higher when compared to the faster big bore magnums, but under actual hunting conditions this is rarely the decisive factor for success. Due to the ratio between the case capacity and the bullet diameter of the .338 it is not a true magnum in the sense that it will not be at its best with the slowest burning powders. It remains, however, a very good cartridge for all-round big game hunting all over the world from deer to the largest antelope.

Norma Brass

Norma Brass is the gold-standard of cartridge cases.

Norma products are known worldwide for high quality. Cartridge cases are an important factor in this reputation. Superior quality ensures a long life and many reloads. Norma cases are made of the best possible raw materials with the narrowest tolerances, and they deliver accuracy round after round.

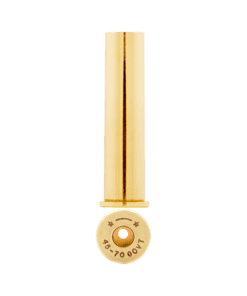

The case neck is annealed to become softer. This prevents gas leaks and enables the case to hold the bullet firmly for at least 10 years without cracking as a result of aging material.

Further down on the case body, the hardness increases to avoid unnecessary stretching. If it is too hard, it would bring the risk of cracks.

Furthest down, around the primer pocket, the brass should be firm. Here, the hardness is nearly twice that of around the neck.

The structure of the material reveals the hardness. During processing the large, soft grains are broken down into smaller ones, which makes for a harder material. At the annealing, small grains become bigger and the hardness decreases.

| Weight | 1.5 kg |

|---|---|

| Dimensions | 25 × 15 × 15 cm |

Be the first to review “Norma Cases 338 Win Mag QTY 50” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.