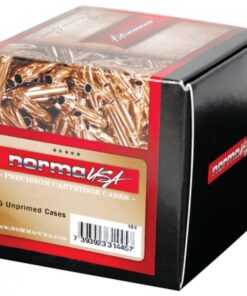

Norma Cases 9.3×62 QTY 50

Sorry, this product is not available to purchase in your country.

R 1,345.43 Incl. VAT

Norma Cases 9.3×62 QTY 50

One of the most underrated cartridges in the U.S. is the 9,3×62 – probably due to the fact that the .366” bullet diameter hardly is known here. The cartridge was designed in 1905 by the German gun maker Otto Bock. His aim was to make an all-round big game cartridge for use in the then German colonies in Africa. It has a slightly larger base diameter and case capacity than the .30-06, but can still be used in a standard length action, and thousands of moderately priced rifles has been made in this caliber ever since. For the same reason the 9,3×62 became an instant success. Not only the German colonists but many farmers all over Africa used it for antelopes and many also killed buffalo and even elephant using solids.

In Europe it remains a popular cartridge for hunting driven game like moose and wild boar, and it is still offered in rifles from most makers here. It would be a very good choice for most hunting in the mountainous parts of North America, and if one should choose a rifle caliber for hoofed game all over the world, this is not an a unlikely candidate.

The heavy bullets combined with a bearable recoil makes it a great choice for hunting in the bush. Due to the moderate velocity and the easily controlled expansion it is a great killer on larger game, and usable in a pinch for even the largest species. Handloaders using modern powders and pointed bullets like the 286 grain Nosler Partition will obtain a comparatively flat trajectory which makes the 9,3×62 ample for hunting anything within normal range – up to 250 or even 300 meters, provided that it is zeroed in at 200 meters. Due to the moderate velocity not even the smaller deer species will normally suffer excessive meat damage when shot with a 9,3×62.

Norma Brass

Norma Brass is the gold-standard of cartridge cases.

Norma products are known worldwide for high quality. Cartridge cases are an important factor in this reputation. Superior quality ensures a long life and many reloads. Norma cases are made of the best possible raw materials with the narrowest tolerances, and they deliver accuracy round after round.

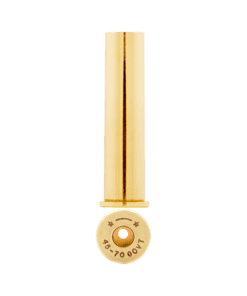

The case neck is annealed to become softer. This prevents gas leaks and enables the case to hold the bullet firmly for at least 10 years without cracking as a result of aging material.

Further down on the case body, the hardness increases to avoid unnecessary stretching. If it is too hard, it would bring the risk of cracks.

Furthest down, around the primer pocket, the brass should be firm. Here, the hardness is nearly twice that of around the neck.

The structure of the material reveals the hardness. During processing the large, soft grains are broken down into smaller ones, which makes for a harder material. At the annealing, small grains become bigger and the hardness decreases.

| Weight | 1.5 kg |

|---|---|

| Dimensions | 25 × 15 × 15 cm |

Be the first to review “Norma Cases 9.3×62 QTY 50” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.